|

|

|

|

|

|

マイレッジマラソンの 燃料計測について

measurement of fuel consumption in MILEAGE MARATHON |

|

Measuring the amount of fuel

in Mileage Marathon is very difficult because factors of missmeasuring

like heat expanding and vapor bubbles are influential strongly to small

quantity of it's fuel consumption.

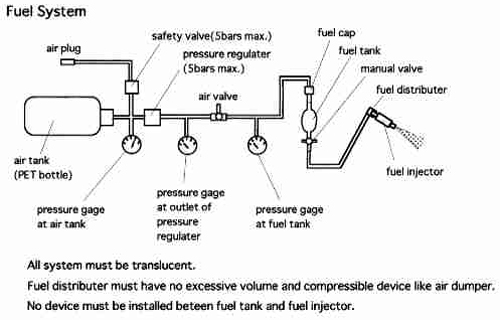

As for the factor of missmeasuring by heat expanding of fuel, It has

been mostly solved by confirmation of air pressured electric fuel injection

system without electric fuel pump that increase temperature of fuel. If

it has only a few volume of fuel except tank in it's hole fuel system, compensating

of heat expanding by just fuel tank is almost accurate.

But as for the factor of missmeasuring by vapor bubbles, It has not

been enough to be solved it yet. The mechanism of the error of measuring

the fuel consumption is as follows. When person put off a cap of fuel

tank to measure the fuel consumption, same fuel vapor occurred by

haste decompression in the fuel distributor even if manual valve of

fuel tank is closed, caused by somewhat unexpected factors.

And there are some volume in fuel injector and fuel distributor

that we can't see in them and can't make sure the amount of vapor

bubbles in them with naked eye.

Particularly, in the case that there is some volume in the fuel

distributor, the error will be happen even if any competitor do not

have a wrong intention.But if there is a big volume in the fuel distributor

or any other compressible device like air dumper, it is out of problem.

For Example

If the potential for the fuel consumption of the competition vehicle

is 2000(km/l) and the distance of competition track is 15(km), the

real fuel consumption is 7.5(cc). But if the remained fuel vapor is

3(cc) that we can't see it in the fuel distributor, the amount of

measuring the fuel consumption is 4.5(cc). Therefore the record is

3333(km/l). The error of measuring the fuel consumption is 67(%).

So we have discussed about how to compensate these bubbles. And then

person in charge of Finish Mileage Marathon offered to us one of good

ways to make sure the vapor bubbles in the fuel distributor.

The important point of improving way is as follows.

|

|

| After topped up ,temperature measured

and repressurized, Measurers will check that fuel-level doesn't drop significantly;

significant drop is over about 0-1mm, which is the usual drop when system

is compressed.(measuring point of fuel tank I.D.is about 3mm) |

|

| Above is very important to accurate measuring

of fuel consumption. |

|

| For reference, whole procedure is as follows. |

|

Here are the top-up procedures

we have planned to apply for pressurized fuel systems.

At the start:

- To speed up the procedure competitor is recommended to come to startline

top-up with fuel left in tank and valve closed with the system after

tank compressed to normal running pressure.

1)fuel is added well above the mark

2)system is compressed to the pressure marked on the meter

3)fuel valve is opened

4)competitor will start the engine, engine must run until the fuel

has dropped under the mark; this is to ensure same pressure in the whole

system as well as to uncover possible 'hide-ups' for fuel

5)valve is closed

6)tank is decompressed

7)fuel is added above the mark

8)temperature is measured

9)fuel will be leveled to mark with syringe

10)system is compressed to the pressure marked on the meter

11)valve is opened

- After this competitor can move to the startline.

At the finish:

- Competitor should not do anything for the vehicle before given permission.

1)valve is closed

2)decompression

3)fuel is topped up with motor-burette

4)temperature is taken

5)system is compressed

6)valve is opened

7)measurers will check that fuel-level doesn't drop significantly;

significant drop is over about 0-1mm, which is the usual drop when system

is compressed.(measuring point of fuel tank I.D.is about 3mm)

|

|

上記計測方法に対して、または燃料計測全般について、御質問、御意見、御相談のある方は、 こちらまで。 |

|

|

|